Reliable solutions for your project

- Fully featured EMS (Electronics Manufacturing Service)

- Quality is our top priority

- 20 years of experience in electronics manufacturing

- ISO 9001 and EASA POA certified

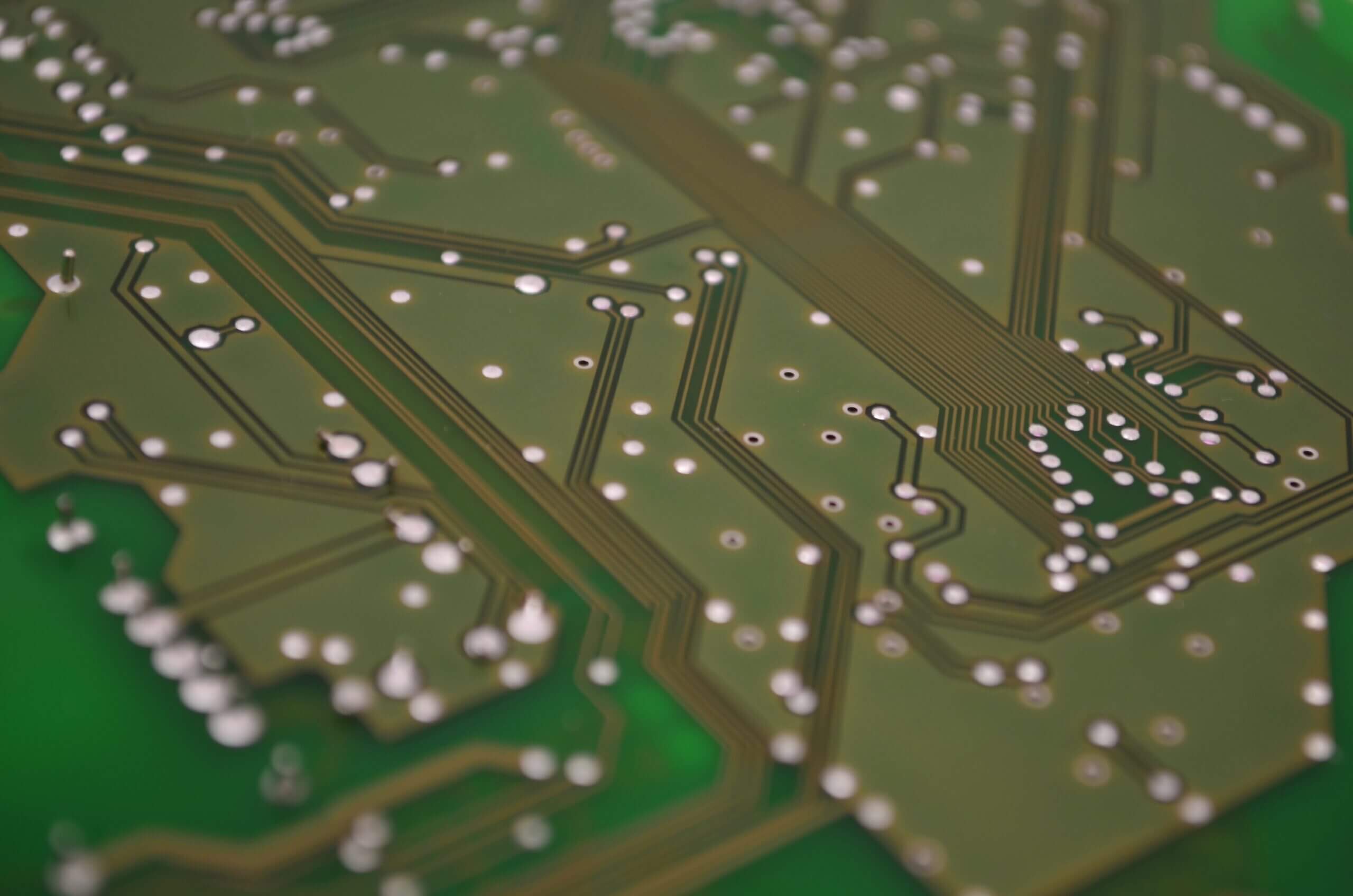

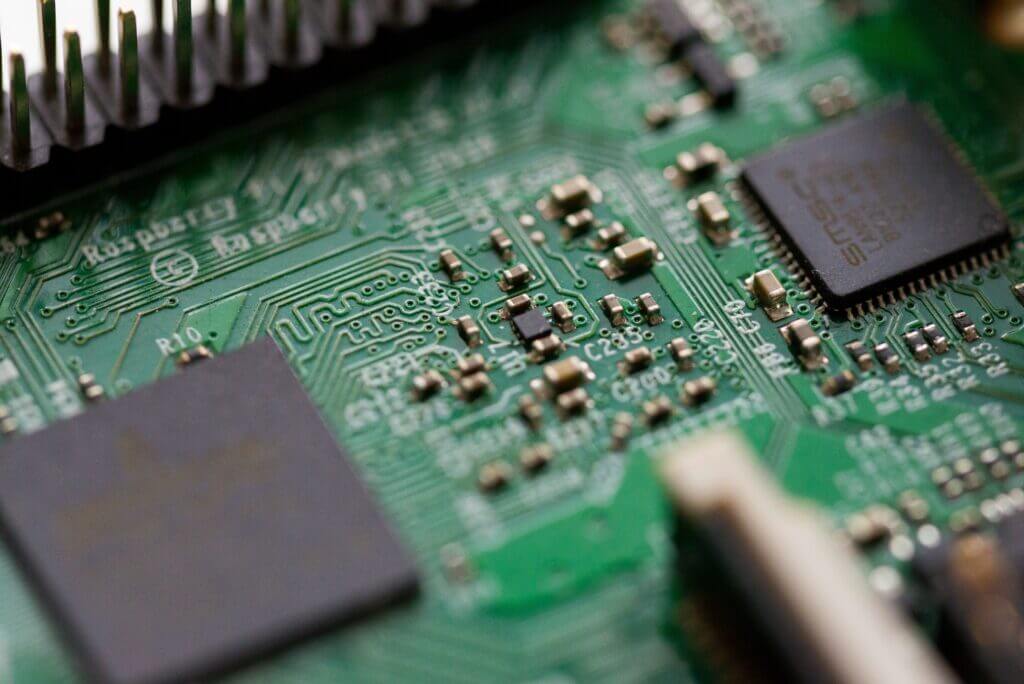

At DevCom, we are a team of experienced professionals with a deep understanding of PCB and electronics manufacturing, with most of us having over 20 years of involvement in the industry. We offer comprehensive production services, ranging from full-scale production to individual parts or specific operations within the production process.

- Complete assembly takes care of the entire production process, including the preparation of printed circuit boards, their production, mediation of component delivery, continuous quality monitoring and final assembly of products.

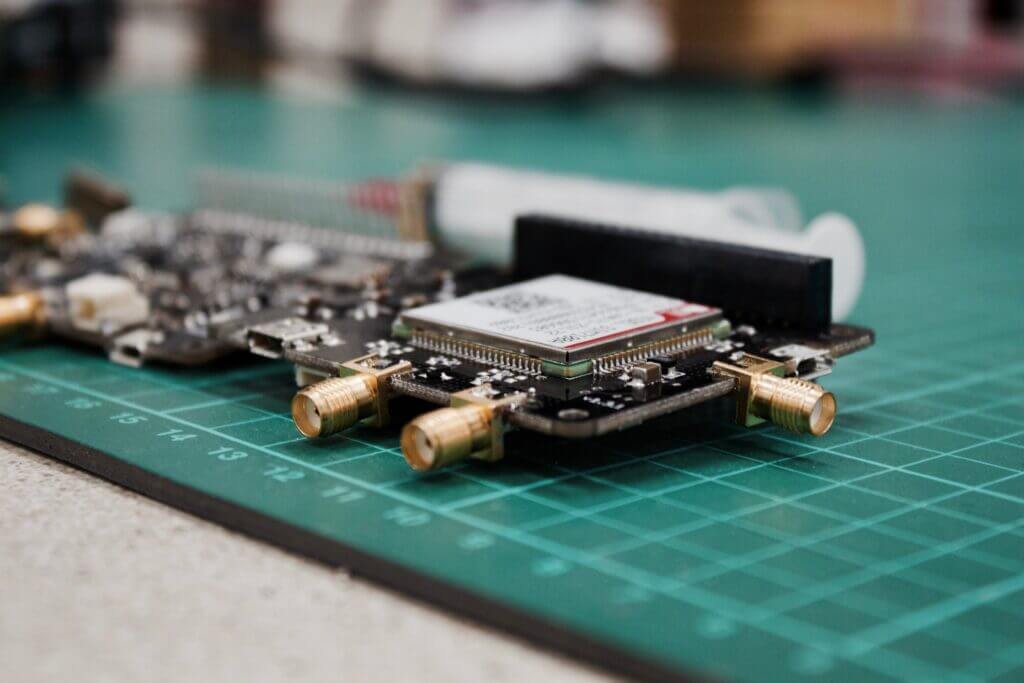

- For a partially provided service, the customer may supply their own PCB, components or a parts thereof. Any remaining parts of the process will be provided by our team.

- We also offer services in PCB repair, assembly of cables and final products on the scale from samples to small or medium sized batches.

Technologies and Equipment

Pre-production

- Preparation based on BOM (Bill of Material), component datasheets and other documentation

- SMT/SMD data generation and analysis based on provided information

- Special requirement implementation, technology restrictions and research of applicable laws and regulations

- Finding suppliers for parts and materials in accordance with set quality requierements

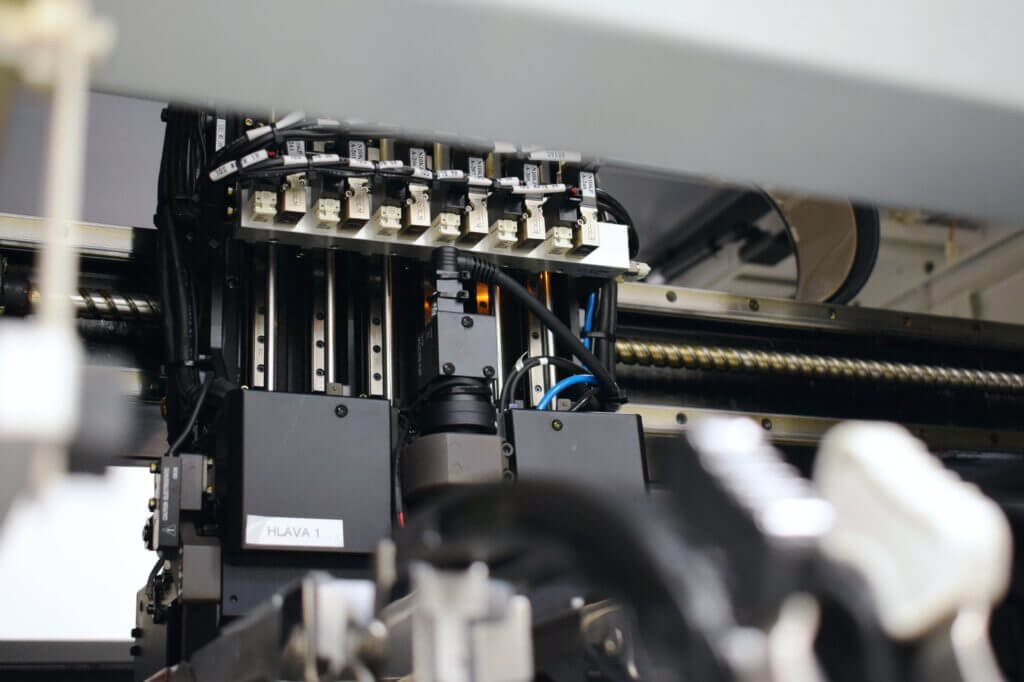

Solder paste application and SMT component mounting

- Automatic paste application

- Manual PBT Uniprint-G stencil printer

- SMT machines by Samsung

- Maximum PCB size for SMT is 450 x 350 mm

- SMT chip component accuracy of ± 40 µm

- In-line SMT line

- BGA size range – 0402 (0.5 x 0.25mm) up to 50 x 50 mm

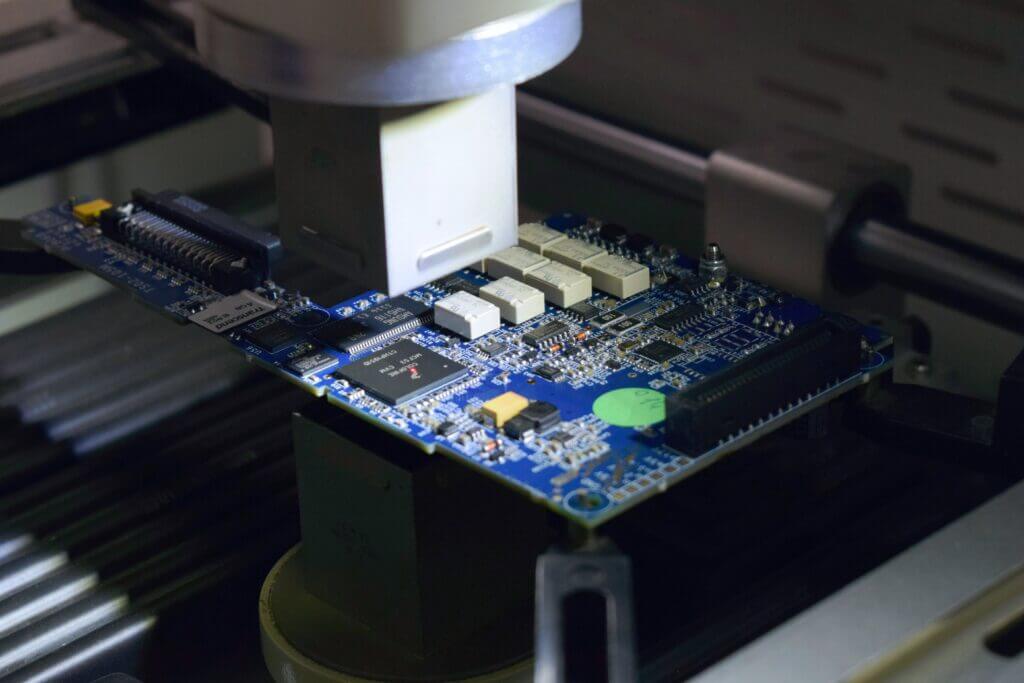

BGA, QFP Soldering

- Professional IBL Reflow furnace, ie. suitable for BGA components

- SMD repair and replacement workstation for CCGA, QFN, CSP, LGA and BGA

Manual mounting and soldering

- OLAMEF forming machines

- Antistatic workplaces

- Welleman hand solders

- Pb-Free technology (Pb soldering also avaliable)

- Kraintek ultrasound cleaner

Assembly and inspection

- Assembly for semi-products, finished products or prototypes

- Thorough quality control of PCBs, products or prototypes

- Visual inspection using microscopes and CCD cameras

Firmware loading and testing

- PCB and assembly testing according to client’s documentation

- Loading, firmware tuning, in-circuit a customer tests

- Fully equipped laboratory with measuring instruments, instruments for testing specific parameters, including dedicated test kits and IT equipment

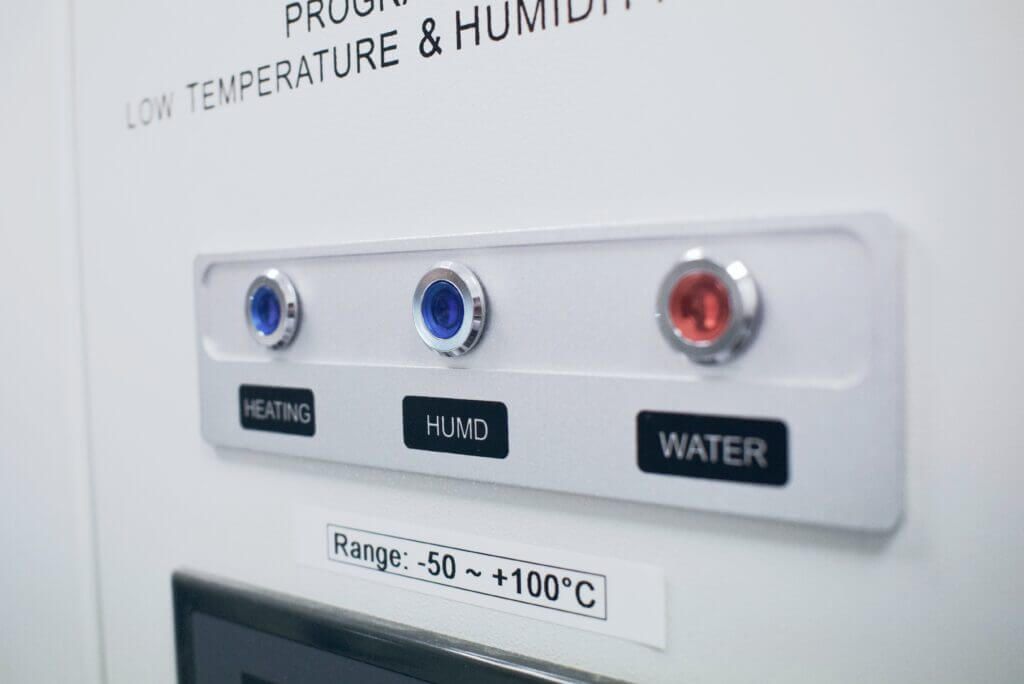

- Vötch climatic chambers for continuous and shock temperature testing